Call Us:

- Home

- / Aluminum Products

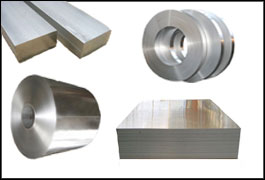

Aluminum Products

Precision Aluminum **foil, sheet, plate, coil** --custom processed to your exact dimensions. **Traceable**, **DFAR/RoHS compliant**.

Aluminum Alloys Offered

- **1100** - corrosion resistance; excellent conductivity

- **1145** - high purity for electrical/packaging

- **1350** - high conductivity for transformers & bus bars (foil/strip/wire)

- **2024** - high-strength aerospace alloy; fatigue resistance

- **3003** - strength + formability; tanks, panels

- **5052** - marine corrosion resistance; pressure vessels

- **6061** - structural; machinable; weldable

- **8011** - engineered for foil applications; barrier performance

Forms & Processing

Foil, sheet, plate, coil, bar & wire - Slitting * Cut-to-length * Blanking * Shearing * Coil leveling

For more specifics about our aluminum products click on the following links:

About Aluminum

Aluminum alloys with a ride range of properties in aluminum alloy are used in engineering structures. Alloy systems are classified by a number system (ANSI) or by names indicating their main alloying constituents (DIN and ISO). Selecting the right alloy for a given application entails considerations of strength, ductility, formability, workability, weldability and corrosion resistance to name a few. Aluminum is used extensively in modern aircraft due to its hight strength to weight ratio.

Wrought Alloys

The International Alloy Designation System is the most widely accepted naming scheme for wrought alloys. Each alloy is given a four-digit number where the first digit indicates the major alloying elements.

1000 Series are essentiallly pure aluminum with a minimum 99% aluminum content by weight and can be work hardened.

2000 Series are alloyed with copper and can be precipitation hardened to strengths comparable to steel.

3000 Series are alloyed with manganese and can be work-hardened.

4000 Series are alloyed with silicon. These are also known as silumin.

5000 Series are alloyed with magnesium and derive most of their strength from work-hardening. It is suitable for cyrogenic applications and low temperature work. That be said this series is susceptible to corrosion above 60 degrees C.

6000 Series are alloyed with magnesium and silicon, are easy to machine, and can be precipitation hardened but not to the high strengths that 2000 and 7000 series can reach.

7000 Series are alloyed with zinc and can be precipitation hardened to the hightest strengths of any aluminum alloy.

8000 Series is a category mainly used for lithium alloys.